Frequent machine breakdowns from scaling, corrosion, dust, and climate exposure.

Difficulty in accessing and servicing remote structures.

Hazardous conditions during maintenance pose safety risks.

Conventional manual monitoring methods not possible under full operating conditions.

Lack of vibration data leads to inefficient maintenance scheduling and reactive strategies.

Robust IoT solution for continuous equipment health monitoring and early issue detection.

Do-It-Yourself guide for easy sensor and gateway setup, suitable even for remote locations.

Real-time data access, alerts, and reports to minimize manual inspections and hazardous condition exposure.

Wireless sensors provide reliable data in full operating conditions, surpassing manual monitoring limitations.

Data-driven plans for preventive maintenance, enhancing equipment efficiency.

Increase revenue and reduce costs with an easy-to-install solution, requiring no extra infrastructure or specialized resources.

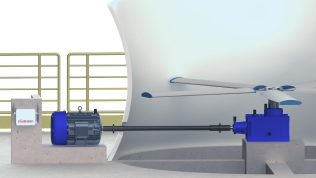

1740 MW Plant 62 Cooling Tower Fans

ROI achieved within 2 months

Downtime Reduced by 80%

Secure and Reliable Data Storage

Integrate with any third party platform

Real Time Automated Alerts and Reports

Advanced ML Algorithms for Fault Detection

Vibration Analyst Expert Insights